- [email protected]

- +86 312 590 7069 / +86 318 769 1559

+86 155 1129 3350

The Introduction of Expanded Metal Mesh

●The Expanded Metal Mesh, also called Expanded Metal or Expanded Metal Sheet, it is one of the most widely used metal wire mesh products. The expanded metal mesh is produced of whole metal sheet by punching and expanding process, the material of expanded metal mesh can be stainless steel, carbon steel, galvanized steel or aluminum. BZWIREMESH produces a variety of expanded mesh with excellent performance, widely applied in construction, manufacturing, decoration, and various other fields, enjoying popularity among users worldwide.

● Features of Expanded Metal Mesh:

1. High Strength:Stainless steel expanded metal exhibits high strength, capable of withstanding significant pressure and tension, making it suitable for manufacturing structural components with high load-bearing requirements.

2. Lightweight:Compared to other metal materials, expanded metal has a relatively light weight, facilitating transportation and installation, suitable for applications demanding lower weight.

3. Corrosion Resistance: Specially treated, expanded metal sheet possesses excellent corrosion resistance, enabling prolonged use in harsh environments.

4. Aesthetic Appeal:Uniform mesh apertures contribute to an aesthetically pleasing appearance. Moreover, customization options allow for unique structures and designs, enhancing the quality of architecture and decor.

● Production Process of Expanded Metal Mesh:

1. Selection of suitable-sized and -thickness metal sheets as raw materials.

2. Determination of hole shapes and sizes based on product requirements, such as diamond-shaped holes, hexagonal holes, etc.

3. Employing professional expanded metal mesh punching and shearing machines with appropriate molds to expand and stretch the metal sheet into the desired steel mesh structure.

4. Straightening and flattening the steel expanded metal.

5. Surface treatments such as degreasing, painting, powder coating, galvanization, passivation, etc.

6. Inspection of product dimensions, appearance, and flatness before packaging and shipment.

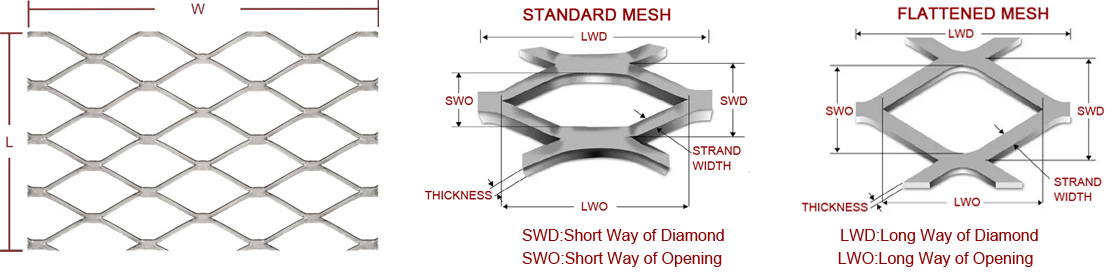

The Parameters and Specifications of Expanded Metal Mesh

Expanded Mesh Specifications generally include the following parameters:

1. Material: Steel, aluminum, stainless steel, copper, etc.

2. Hole Shapes: Diamond, fish scale, hexagonal, turtle shell, etc.

3. Mesh Opening Dimensions:

Short Way of Design (SWD): The short diamond diagonal length from node center to node center.

Long Way of Design (LWD): The long diamond diagonal length from node center to node center.

Short Way of Opening (SWO): The short diamond diagonal length.

Long Way of Opening (LWO): The long diamond diagonal length.

4. Strand Width: The width of each edge of the mesh aperture, typically equal to or greater than the plate thickness, determining mesh hardness and weight.

5. Plate Thickness: Thickness of the raw material steel plate for the expanded metal screen, a crucial specification for custom expanded metal.

6. Outer Dimensions: Width and length of the expanded mesh panels.

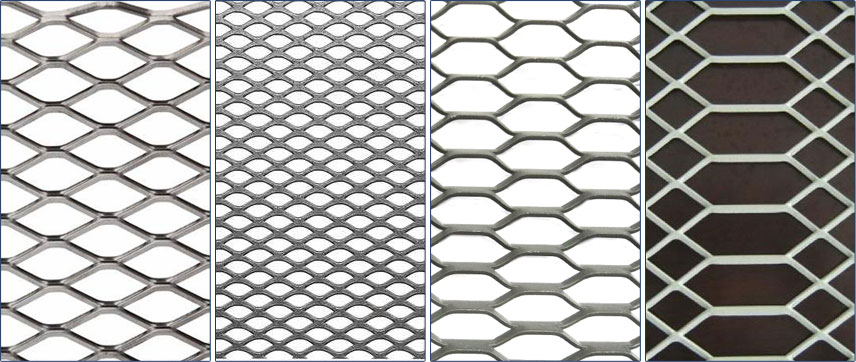

Illustration of expanded metal mesh hole shapes:

|  |  |  |

Diamond hole | Scalelike hole | Hexagonal hole | Complex typ |

Following is the common specifications of expanded mesh(Diamond hole):

| Common Specification of Expanded Metal | |||

| Plate Thickness | SWD | LWD | Strand |

| mm | mm | mm | mm |

| 0.5 | 3 | 6 | |

| 3.2 | 8 | ||

| 5 | 10 | ||

| 6 | 12.5 | ||

| 7 | 14 | ||

| 8 | 16 | ||

| 9 | 20 | ||

| 12 | 30 | 1.35 | |

| 10 | 25 | 1.12 | |

| 0.8 | 10 | 25 | 1.12 |

| 12 | 30 | 1.35 | |

| 15 | 40 | 1.68 | |

| 1 | 10 | 25 | 1.12 |

| 12 | 30 | 1.35 | |

| 15 | 40 | 1.68 | |

| 1.2 | 10 | 25 | 1.13 |

| 12 | 30 | 1.35 | |

| 15 | 40 | 1.68 | |

| 18 | 50 | 2.03 | |

| 1.5 | 15 | 40 | 1.69 |

| 18 | 50 | 2.03 | |

| 22 | 60 | 2.47 | |

| 29 | 80 | 3.25 | |

| 2 | 18 | 50 | 2.03 |

| 22 | 60 | 2.47 | |

| 29 | 80 | 3.26 | |

| 36 | 100 | 4.05 | |

| 44 | 120 | 4.95 | |

| 3 | 36 | 100 | 4.05 |

| 44 | 120 | 4.95 | |

| 55 | 150 | 4.99 | |

| 65 | 180 | 4.6 | |

| 4 | 22 | 60 | 4.5 |

| 30 | 80 | 5 | |

| 38 | 100 | 6 | |

| 5 | 24 | 60 | 6 |

| 35 | 80 | 6 | |

| 38 | 100 | 7 | |

| 56 | 150 | 6 | |

| 76 | 200 | 6 | |

| 6 | 32 | 80 | 7 |

| 38 | 100 | 7 | |

| 56 | 150 | 7 | |

| Other specifications can be customized according to clients' requirement | |||

Classification and Applications of Expanded Metal Mesh

Expanded Metal Mesh serves as a widely used practical material in various fields such as construction, automotive, petrochemical, shipbuilding, and more. Its unique design and manufacturing processes ensure crucial applications in multiple sectors. Here are some primary applications of different types of expanded metal mesh sheet:

● Standard Expanded Steel Mesh: Made from ordinary low-carbon steel plates, galvanized plates, cold plates, etc., possessing high strength and load-bearing capacity, commonly used in construction, machinery, petroleum, and chemical fields.

● Expanded Stainless Steel Mesh:Manufactured from stainless steel sheets, offering excellent corrosion resistance and aesthetics, stainless steel expanded metal

is commonly used in food, medical, and chemical industries.

● Galvanized Expanded Metal Mesh: Ordinary low-carbon steel plates undergo galvanization, enhancing corrosion resistance and appearance, frequently used in construction, fencing, etc.

● Aluminum Expanded Metal Mesh: Produced from pure aluminum or aluminum alloy sheets, lightweight and aesthetically pleasing, often used in decoration, construction, etc.

● Expanded Copper Mesh:Utilizing copper plates, providing high conductivity and corrosion resistance, commonly used in power and electronic fields.

● Guardrail Steel Mesh: Made from thicker steel plates and larger mesh openings, frequently used in roadways, bridges, and safety protection.

● Architectural Expanded Steel Mesh:Utilizing thicker steel plates and larger mesh openings, commonly applied for reinforcing and decorating exterior walls, roofs, etc., of buildings.

● Slope Protection Expanded Mesh: Made from thicker steel plates and larger mesh openings, often used for slope protection and reinforcement along riverbanks and embankments.

Frequently Asked Questions About Expanded Metal

1. What are the benefits of expanded metal mesh?

Expanded mesh is a lightweight, versatile material with a higher strength-to-weight ratio than sheet metal. The process of expanding the metal from its solid sheet form actually strengthens the material. Because the mesh is made from a single piece of metal, further processing such as shearing or pressing is possible.

Expanded metal mesh reduces weight and metal, allowing light, liquid, sound and air to pass freely while providing a decorative or ornamental effect. Expanded metal is a cost-effective alternative to perforated metal since there is no metal loss during the expansion process.

Expanded metal products are ideal for non-slip surfaces. The attractive diamond pattern also makes expanded metal ideal for architectural designs.

2. What materials is expanded metal mesh made of?

There are many kinds of materials from which expanded metal mesh can be made. BZWIREMESH can provide aluminum expanded metal sheet, carbon steel, galvanized steel, nickel, silver, copper and stainless steel expanded metal sheet.

3. What are the main types of expanded metal mesh?

● Standard expanded metal mesh

Standard expanded or raised metal mesh is the finished product from a press after die cutting and expansion. It is an extremely versatile and economical product. It is available in your choice of material, gauge and opening size. Standard expanded metal sheets are ideal when a raised, non-slip surface is required. It is available in aluminium, carbon steel, galvanized steel or stainless steel, providing maximum flexibility to meet project requirements.

● Flat expanded metal mesh

Flattened expanded metal mesh is cold rolled through a machine that flattens the metal after the expansion process, ideal for architectural design trim applications that require flexibility while still maintaining maximum strength and durability. It is the best choice when a smooth surface is required. BZ wire mesh stocks flat expanded metal in a variety of metal materials, thicknesses and opening sizes.

4. How many surface treatment methods of expanded metal?

Expanded metal finishes and special treatments:

· Polished

· Carbon steel: lightly oiled, requires cleaning with an acid or solvent bath and rinse with water prior to final surface preparation

· Aluminum: Clean with a non-etching chemical or cleaner, then rinse and dry thoroughly

· Hot Dip Galvanized: A protective layer of zinc; may have a rough, uneven appearance. Not available for patterns smaller than 1/4"

· Electro-galvanized: Galvanized sheet to provide weather resistance

· Deburring: Remove burrs and sharp edges with a wire brush.

5. Why is open area percentage important for expanded metal?

The percentage of open area determines the amount of space available for air, water and light to pass through the expanded metal panels.

6. What to Consider When Customizing Expanded Metal Mesh?

Custom expanded metals come in a variety of patterns and can be manufactured in unique shapes and sizes. Materials that can be fabricated include aluminum, carbon steel, galvanized steel, and stainless steel. When choosing expanded metal mesh, users should consider several aspects such as material, opening size, and application. If they cannot determine the type and specifications of the product, they can decide to purchase after trying out samples. If you are looking for high quality expanded metal mesh from trusted supplier, welcome to contact us for more information!

Tags

INQUIRY FOR OUR PRODUCT