- [email protected]

- +86 312 590 7069 / +86 318 769 1559

+86 155 1129 3350

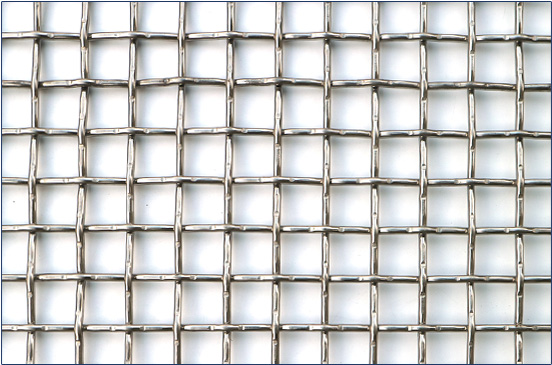

The introduction of stainless steel crimped wire mesh

●Overview: Crimped wire mesh is a type of woven wire mesh. Its materials can include galvanized iron wire, black steel wire, stainless steel wire, copper-clad steel wire, and so on. Stainless steel crimped wire mesh, as a type of stainless steel woven wire mesh, is an important variant of stainless steel wire mesh. This is because stainless steel crimped woven wire mesh typically has a thicker wire diameter and is also known as heavy-duty stainless steel wire mesh.

Stainless steel crimped wire mesh is crimp the metal wire first, and then woven the wire into mesh. Because of the special woven craft, it is very suitable to produce the wire mesh with thick wire. The structure of stainless steel crimped wire mesh is very stable and with good outlook. It is normally used for screening of granules or the decoration and protection for architecture. Stainless steel woven wire mesh is widely used in food, mining, chemical, pharmaceutical, petroleum, metallurgy, machinery, protection, construction, handicrafts and other industries.

● Material: Stainless steel wire 301, 302, 304, 304L, 316, 316L, 321

● Stainless Steel Woven Wire Mesh Features:

1.Strong structure and stable surface.

2.Strong impact resistance and good wear resistance.

3.Uniform mesh size, flat surface, good outlook.

4.High temperature resistance, acid and alkali resistance, corrosion resistance.

5.Various materials and specifications available.

6.Easy to process and widely used.

The woven craft of stainless steel crimped wire mesh

The main difference between stainless steel crimped wire mesh and plain weave stainless steel wire mesh lies in the weaving method. Crimped wire mesh is pre-bent before weaving the stainless steel wire mesh. According to the wire diameter and opening size matches, or according to clients' requirements, crimped wire mesh can be further classified into several types, such as Plain Crimped Woven Wire Mesh, Intermediate Crimped Wire Mesh or Intercrimped Wire Mesh, Lock Crimped Wire Mesh/Screen, Flat Top Wire Mesh, and others.

|  |  |  |

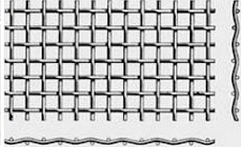

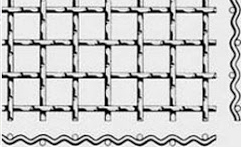

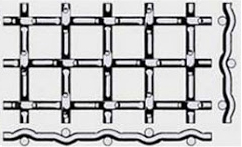

Plain Crimped | Intermediate Crimped | Lock Crimped | Flat Top Crimped |

●Bi-directional Bending Crimped Wire Mesh is suitable for stainless steel woven wire mesh with fine wire diameters and large mesh openings. Plain Crimp refers to the weaving method where each warp wire passes over and under each weft wire, forming a 90-degree angle between the warp and weft wires. This "up/down" weaving locks the mesh in place using the strength of the metal wire and the size of the mesh openings. The warp and weft wires usually have the same diameter.

●Intermediate Crimped Wire Mesh (Intercrimped Wire Mesh) is the most common variety of crimped wire mesh and is widely used in stainless steel woven wire mesh with fine wire diameters and large mesh openings. Intercrimped Wire Mesh is characterized by using relatively thinner metal wires to create larger mesh openings. Typically, the larger the mesh size, the more times the wires are crimped. The crimps on the metal wires of Crimped Wire Mesh increase the stability of the woven stainless steel mesh.

●Lock Crimped Wire Mesh/Screen is suitable for stainless steel woven wire cloth with high mesh precision. Lock Crimped Wire Mesh features protrusions or joints on each intersecting set of metal wires. These joints lock the mesh in place and create an extremely rigid product. Lock Crimped Wire Mesh has uniform mesh openings, precise sieving, high wear resistance, and a long service life.

●Flat Top Wire Mesh has all its undulations bent in one direction, leaving the other side smooth. The surfaces of all the metal wires are aligned with each other to present a flat appearance on the front side of the wire mesh. The undulations on the back side are approximately twice the crimp height of tightly locked crimped wire mesh. The original purpose of developing flat top crimped wire mesh was to provide a smooth surface for material flow or to be used as a supporting screen for finer mesh openings. Additionally, it is widely used in the construction industry.

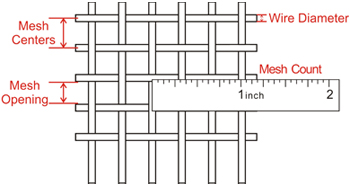

The parameters and specifications of stainless steel crimped wire mesh

The main parameters of stainless steel crimped wire mesh is wire diameter, mesh opening, mesh width and length.

●The wire diameter range is from 0.45mm to 10mm.

●The mesh opening range is from 0.6mm to 150mm.

●The common width of the mesh is 1m~5m, and common used width is under 2m.

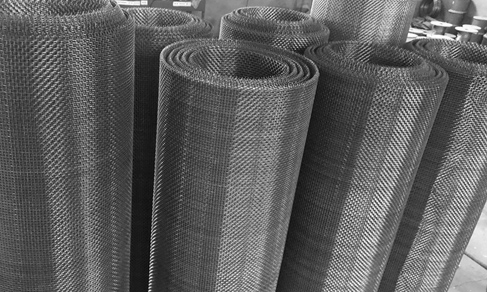

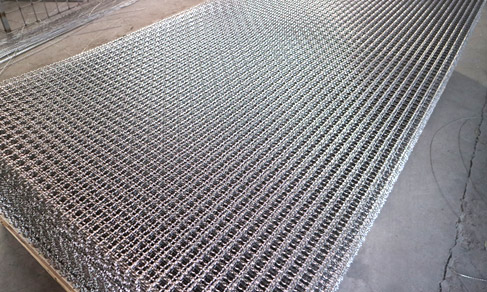

●The stainless steel crimped wire mesh is normally produced in rolls or in panels.

The stainless steel crimped wire mesh is normally produce of SS304 or SS316 hard wire. And carbon steel, per-galvanized carbon steel, brass and copper are also the normal used material for stainless steel woven wire mesh.

|  |

| Crimped wire mesh rolls | Crimped wire mesh panels |

Following is the common specifications of stainless steel crimped wire mesh:

| Common Specifications of Stainless Steel Crimped Wire Mesh | |||

| Mesh Opening (mm) | Wire Dia (mm) | Mesh/Inch | Wire Dia (mm) |

| 2 | 0.5-1.6 | 3 | 0.8-3.0 |

| 2.5 | 0.6-2.0 | 4 | 0.6-2.5 |

| 3 | 0.6-2.5 | 5 | 0.6-2.0 |

| 4 | 0.6-3.0 | 6 | 0.6-1.8 |

| 5 | 0.6-3.5 | 7 | 0.6-1.6 |

| 6 | 0.7-3.0 | 8 | 0.6-1.5 |

| 7 | 0.8-3.0 | 10 | 0.45-1.2 |

| 8 | 0.8-3.5 | 12 | 0.45-1.0 |

| 10 | 0.9-6.0 | 14 | 0.45-0.8 |

| 12 | 1.0-6.0 | 16 | 0.45-0.7 |

| 15 | 1.2-6.0 | 20 | 0.45-0.6 |

| 20 | 1.5-6.0 | ||

| 25 | 1.8-6.0 | ||

| 30 | 2.0-6.0 | ||

| 40 | 2.5-6.0 | ||

| Please Contact Us for Other Specifications | |||

Uses of Stainless Steel Crimped Wire Mesh

Crimped wire mesh is widely used in industries such as mining, chemical, pharmaceutical, petroleum, metallurgy, machinery, protection, construction, and crafts. Due to the special properties of stainless steel material, stainless steel crimped wire mesh is commonly used in industries with strict stability requirements. For example, in the food industry, ss woven wire mesh is used to make food baskets, in the chemical industry for screening and filtration under acidic and alkaline conditions. Stainless steel wire cloth is used as an acid cleaning mesh in the electroplating industry, a mud mesh in the petroleum industry, architectural woven wire mesh in architectural decoration, and oil-water separators in the automotive industry.

Tags

INQUIRY FOR OUR PRODUCT