- [email protected]

- +86 312 590 7069 / +86 318 769 1559

+86 155 1129 3350

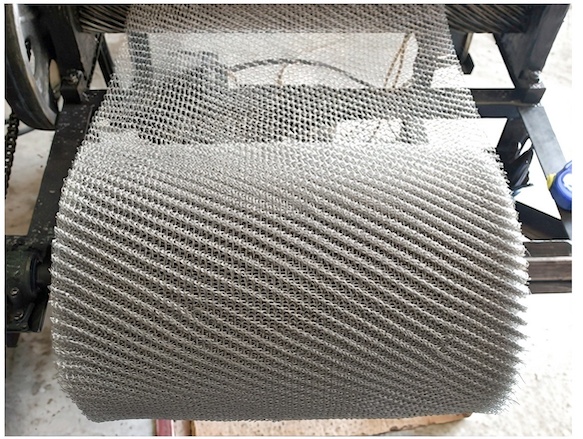

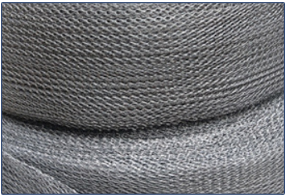

Knitted Wire Mesh: An Overview

Knitted Wire Mesh, also referred to as demister mesh, mist eliminator mesh, or braided wire mesh, is a versatile material manufactured using a knitting process similar to that used in textile production. Its unique structure makes it highly effective for capturing and removing liquid droplets and mist from gas streams in a variety of industrial processes.

Knitted Wire Mesh, also referred to as demister mesh, mist eliminator mesh, or braided wire mesh, is a versatile material manufactured using a knitting process similar to that used in textile production. Its unique structure makes it highly effective for capturing and removing liquid droplets and mist from gas streams in a variety of industrial processes.

Key Features & Benefit

· Efficient gas-liquid separation in applications such as distillation, absorption, evaporation, and catalysis

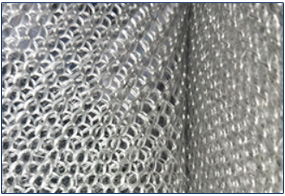

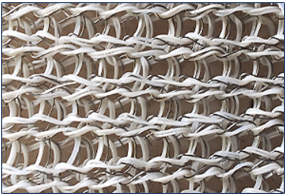

· Customizable knitting styles, including single-ply, multi-ply, and hybrid metal-fiber constructions

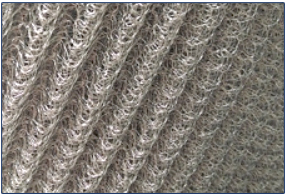

· Can be produced in flat or corrugated forms to suit different flow and separation requirements

· Suitable for a wide range of industrial environments due to its durability and chemical resistance

|  |  |  |

|  |  |  |

Product Specifications

Material Options:

· Stainless steel wires (AISI 201, 202, 301, 302, 304, 304L, 321, 316, 316L, etc.)

· Specialty metals: nickel, titanium, Monel, galvanized steel

· Composite knitting: metal wires combined with cotton, PP, PE, PVC, PTFE, or other synthetic fibers

Wire Diameter:

· Standard range: φ0.12mm – φ0.28mm (stainless steel)

Common Widths:

· 50mm to 600mm (typical: 100mm, 150mm, 300mm, 400mm, 450mm, 500mm, 520mm, 560mm)

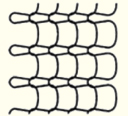

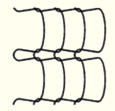

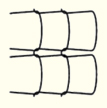

Available Types:

· Standard Type: General-purpose mist elimination

· High-Efficiency Type: Enhanced droplet capture for fine mists

· High-Penetration Type: Lower pressure drop for high-flow systems

| Standard Type | |

| Typical wire diameter (mm) | Range of natural width (mm) | |

| 0.12-0.28 | 30-1000 | |

| Typical number of stitches per cm on length | Typical number of stitches per cm across lay flat | |

| 0.6 | 1.9 | |

| High-efficiency type | |

| Typical wire diameter (mm) | Range of natural width (mm) | |

| 0.12-0.28 | 30-550 | |

| Typical number of stitches per cm on length | Typical number of stitches per cm across lay flat | |

| 1.6 | 0.74 | |

| High-penetration type | |

| Typical wire diameter (mm) | Range of natural width (mm) | |

| 0.12-0.28 | 330-350 | |

| Typical number of stitches per cm on length | Typical number of stitches per cm across lay flat | |

| 0.5 | 0.5 | |

Applications of Knitted Wire Mesh

Knitted Wire Mesh is widely used across multiple industries for separation, filtration, and protection purposes. Common applications include:

· Oil & Gas / Petrochemical: Demisters in distillation columns, scrubbers, and knockout drums

· Chemical Processing: Mist elimination in reactors, evaporators, and absorbers

· Environmental & Air Pollution Control: Dehydration, demisting, and dust removal in emission control systems

· Pharmaceuticals & Food Processing: Filtration and separation in hygienic process systems

· Aerospace, Automotive & Machinery: Noise reduction, vibration damping, and EMI shielding

· Instrumentation & Electronics: Shielding against electromagnetic interference and mechanical buffering

Knitted Wire Mesh Demisters

Knitted wire mesh demisters are specialized gas-liquid separators designed to remove entrained droplets and mist from process streams. As gas flows through the mesh pad, liquid particles coalesce on the wire surfaces and are drained away, resulting in cleaner gas output.

Design & Construction:

· Mesh pads made from knitted wire mesh

· Supported by grid structures and mounting frames

· Customizable shapes: round, square, or irregular designs

· Large units can be modularized for easy installation and maintenance

Industries Served:

· Chemical and petrochemical plants

· Refineries and gas processing

· Sulfuric acid and fertilizer production

· Pharmaceutical and food & beverage

· Environmental and air treatment system

Why Choose Our Knitted Wire Mesh?

· Customizable: Tailored to your specific process and dimensional requirements

· Durable: Made from high-quality materials for long service life

· Versatile: Suitable for a broad range of temperatures, pressures, and corrosive environments

· Expert Support: Technical assistance available to help you select the right mesh type and configuration

✅ Contact Us for a quote or to discuss how knitted wire mesh can improve your process efficiency and product quality.

Tags

INQUIRY FOR OUR PRODUCT